"Henry Diesel" (default)

"Henry Diesel" (default)

08/15/2014 at 03:01 • Filed to: Graveyard Shift, Turbo

2

2

13

13

"Henry Diesel" (default)

"Henry Diesel" (default)

08/15/2014 at 03:01 • Filed to: Graveyard Shift, Turbo |  2 2

|  13 13 |

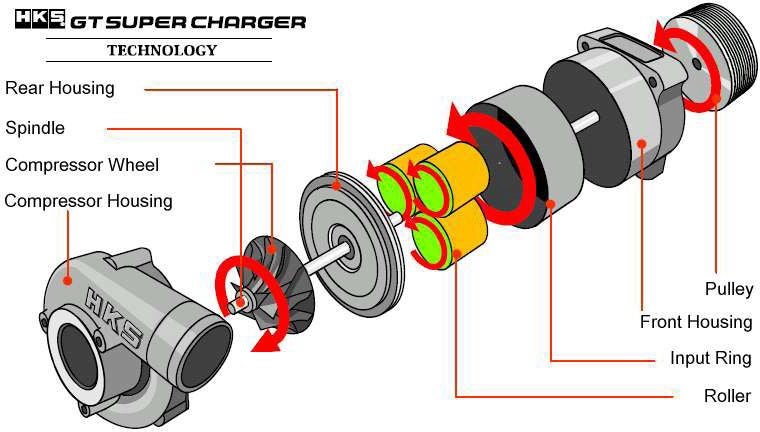

A Pretty picture but Im still not sure how it works.

Denver Is Stuck In The 90s

> Henry Diesel

Denver Is Stuck In The 90s

> Henry Diesel

08/15/2014 at 03:02 |

|

I know the gist of how they work, but thats still not enough

Mr. FiSTer of Team FiST Fetish

> Henry Diesel

Mr. FiSTer of Team FiST Fetish

> Henry Diesel

08/15/2014 at 03:19 |

|

Magic?

Sam

> Henry Diesel

Sam

> Henry Diesel

08/15/2014 at 03:20 |

|

Magic, obviously.

All Motor Is Best Motor

> Henry Diesel

All Motor Is Best Motor

> Henry Diesel

08/15/2014 at 03:44 |

|

This one of those centrifugal superchargers?

Saf1

> Henry Diesel

Saf1

> Henry Diesel

08/15/2014 at 04:27 |

|

Based on this pic, I wonder if one can have an integrated twincharger unit? I think so far they combine an SC and turbo but they are separate to my knowledge. From this pic it seems quite possible (I mean that is literally a turbo with a pulley system)

Saf1

> Henry Diesel

Saf1

> Henry Diesel

08/15/2014 at 04:28 |

|

My basic understanding: Pulley is belt driven by the engine itself. Pulley spins compressor wheel (turbine?!) to draw more air into compressor and hence more air/second enters engine - more oxygen available to combust fuel with - more power/stroke >:) It seems like the rollers would increase rotation speed from input ring and spindle a further increase in rotation speed (ie gears getting relatively smaller, therefore spinning faster than input) as you don't need much torque to spin a turbine compared to the relatively massive amount coming from the engine. This is why I'd guess superchargers sap a certain amount of power more than a turbo (more moving parts [friction])

Btw a turbo works in similar principle except rather than being driven by the engine itself, it is driven by exhaust pressure spinning the turbine

Henry Diesel

> Sam

Henry Diesel

> Sam

08/15/2014 at 06:01 |

|

that or witchcraft

Henry Diesel

> Mr. FiSTer of Team FiST Fetish

Henry Diesel

> Mr. FiSTer of Team FiST Fetish

08/15/2014 at 06:03 |

|

Uuunnngghhh goes in, heeeeeee comes out.

samssun

> Henry Diesel

samssun

> Henry Diesel

08/15/2014 at 06:07 |

|

Pistons turn crankshaft. Crankshaft pulley turns power steering, alternator, and supercharger pulleys (top right of picture) via belts.

Compressor wheel spins with the crankshaft, pulling air in the front of the housing (bottom left of picture), and flinging it around and out the side of the housing, which connects to the engine intake (usually through an intercooler).

The size of the supercharger pulley determines the ratio of engine to supercharger speed, but since they're tied together directly, you have more linear boost than a turbo.

Saf1

> samssun

Saf1

> samssun

08/15/2014 at 06:17 |

|

Is there an exponential increase in exhaust emissions with increased rpm? Why do you not get a linear boost with turbos like with superchargers? Or is that due to the properties of gases?? Also when they tune turbos for low rpm, are they not merely sapping its potential for high rpm performance? I mean what else would such a system incorporate apart from smaller turbine/housing for reduced spool time?

samssun

> Saf1

samssun

> Saf1

08/15/2014 at 06:54 |

|

A positive displacement supercharger (the kind with rotating lobes) moves a fixed amount of air with each rotation, so it's truly linear. A centrifugal SC like this one is going to be somewhere in between.

I don't think exhaust increases exponentially/quadratically with rpm, but a turbo below a certain rpm builds no boost, and above a certain speed you're outside the efficient range, so you have to limit speed via the wastegate.

So in practice your turbo has a much narrower range than the engine, and you have to choose what to optimize. When you hear people talk about turbos having more torque, they mean that compared to Audi & BMW's high-rpm-optimized V8s, the BMW N54 & N55, Ecoboost, VW 1.8/2.0T, etc are low-rpm, response optimized.

They use a tiny turbo which doesn't have much inertia, and a tiny housing which means good velocity at minimal exhaust flow, to get you that 1500 rpm spool. But then you have a restriction at high rpm. Shifting at 6000 where you hit a wall is the tradeoff you make for quick spool.

Going the other way, you could size your single Supra turbo to flow well at redline and give you a big power number, and have no boost below 4500. Compared to the domestic V8 making crazy torque from 1500 and thus not optimizing much above 7k, the roles will be switched.

Nibbles

> Henry Diesel

Nibbles

> Henry Diesel

08/15/2014 at 08:22 |

|

Belt drives pulley, which drives the input ring in a counter-clockwise rotation. The inner edge of the input ring drives the rollers in a counter-clockwise rotation. The spindle is placed on the inside edges of the rollers, making contact and thus spinning the spindle in a clockwise rotation. The spindle spins the compressor in a clockwise rotation which is situated in the compressor housing. Air comes in the center of the compressor housing and is compressed by the compressor, being ejected at the outlet pipe (the part with the HKS logo on it).

In essence it's a belt-driven, planetary-geared, compressor.

uofime

> Henry Diesel

uofime

> Henry Diesel

08/15/2014 at 12:25 |

|

I'm guessing rollers = planetary gears and that whole section is a planetary gear set so the slow crank can turn the compressor fast enough to make the desired boost